Light plastic

By Lydialyle Gibson

Photography by Lloyd DeGrane

Since 1940, when Bell Laboratories electrochemist Russell Ohl exposed a silicon wafer to bright light and saw its electrical current jump, silicon has dominated solar-cell technology. The first commercially viable “solar battery,” unveiled by three other Bell Labs researchers 14 years after Ohl’s discovery, was a positively charged silicon strip that could convert 6 percent of sunlight into electricity. Today the metalloid claims 90 percent of the photovoltaics market.

But silicon is expensive. Material and manufacturing costs make the highest-efficiency solar cells prohibitive. Commercially marketed solar cells run at about 15 percent efficiency, but even those can be expensive and difficult to commercialize.

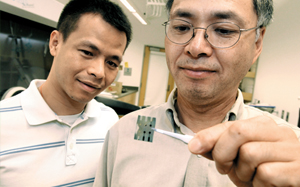

Plastic, cheaper and more flexible than silicon, may provide a solution. One California company, Solarmer Energy Inc., is incorporating the work of two Chicago chemists into a plastic solar cell built to power portable electronic devices. Luping Yu, a chemistry professor, and Yongye Lang, a graduate student, invented PTB1, a semiconducting polymer whose active layer measures 100 nanometers thick, the width of about 1,000 atoms.

Synthesizing even a small amount of PTB1 is a multistep, time-consuming process, but its engineering is far simpler than that of other polymers with similar efficiencies. “We think that our system has potential,” Yu says. Solarmer’s finished solar cell—an eight-square-inch prototype is under construction—is expected to achieve 8 percent efficiency and last at least three years, with an eye toward improving those numbers in the future. Although plastic technology has so far lagged behind silicon, says Solarmer executive Dina Lozofsky, “new materials with higher efficiencies are really the key in our industry.”

Return to top